Table of Contents

Introduction Aluminum has become a cornerstone in modern industrial applications, thanks to its unique properties and versatility. Among its various forms, aluminum sheet metal fabrication stands out as a critical material for metal fabrication due to its lightweight, durability, and adaptability. This blog will highlight five key advantages of aluminum sheet metal fabrication that make it indispensable across industries.

Lightweight Advantage

One of the most significant benefits of aluminum is its low density, which results in lightweight components. Compared to other metals like steel, aluminum is about one-third the weight, making it an ideal choice for industries prioritizing weight reduction.

- Applications in Transportation: In the automotive and aerospace sectors, aluminum sheet metal fabrication reduces the overall weight of vehicles, leading to improved fuel efficiency and lower emissions. For instance, aluminum is widely used in aircraft structures, where every kilogram saved can significantly enhance performance and reduce costs.

- Portability in Electronics: For electronic devices requiring portability, such as laptops and smartphones, aluminum sheet metal fabrication provides a durable yet lightweight solution, offering both protection and convenience.

Superior Corrosion Resistance

Aluminum naturally forms a thin, protective oxide layer on its surface, which shields it from further oxidation and corrosion. This characteristic makes aluminum suitable for use in harsh environments.

- Performance in Challenging Conditions: In humid or chemically aggressive environments, aluminum outperforms metals like iron and steel. It is commonly used in chemical containers, marine applications, and architectural cladding due to its ability to resist corrosion without requiring additional coatings.

Excellent Thermal Conductivity

Aluminum is an outstanding conductor of heat, making it ideal for applications that demand efficient heat dissipation.

- Enhanced Heat Management: In electronics, aluminum sheets are used in heat sinks to manage and dissipate heat from critical components, ensuring optimal performance and extended lifespan. Similarly, in cookware, aluminum’s thermal properties lead to faster and more even heating, enhancing cooking efficiency.

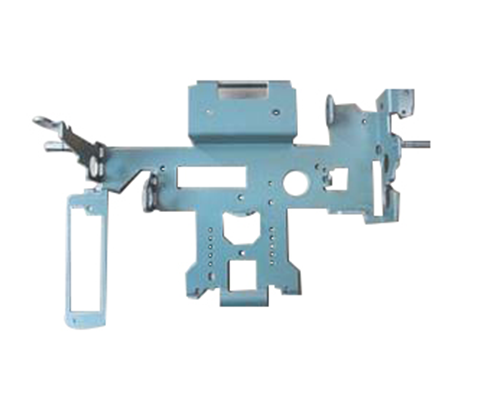

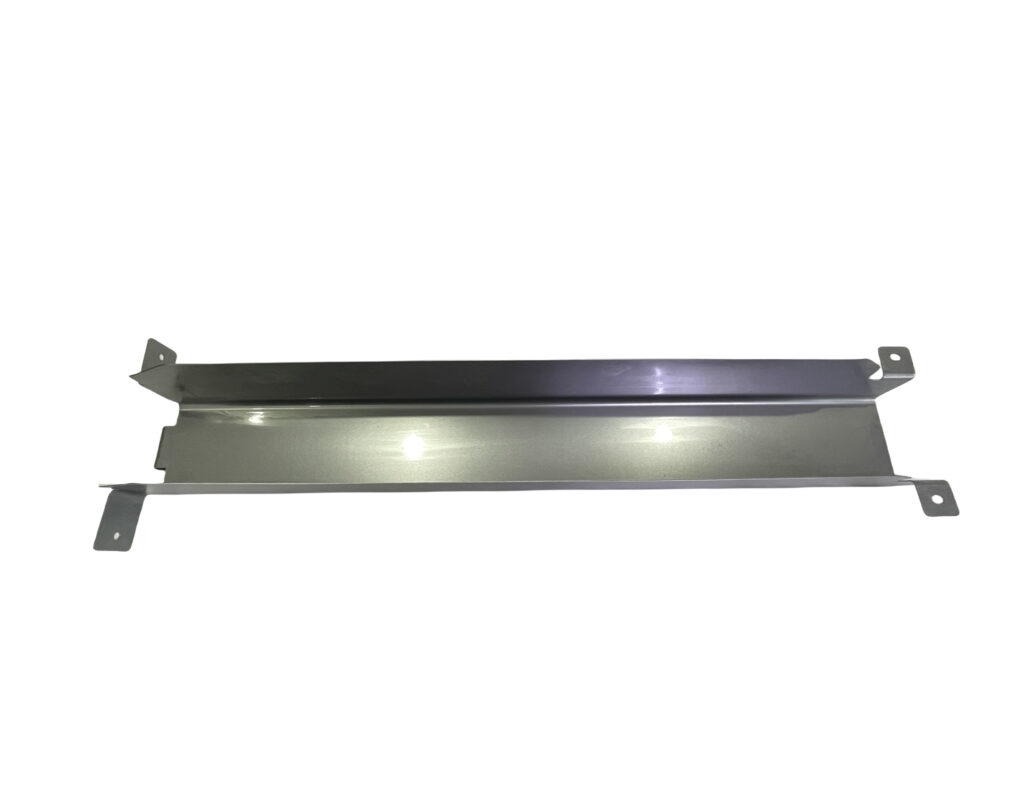

Easy Fabrication

aluminum sheet metal fabrication is highly malleable and can be easily processed through common fabrication techniques such as cutting, stamping, bending, and welding. This makes it a practical choice for manufacturers.

- Efficient Manufacturing Processes: Aluminum’s ease of fabrication translates to lower production costs and faster turnaround times. For example, the automotive industry benefits from aluminum’s workability when producing complex, lightweight body panels and components.

- Precision in Complex Designs: Manufacturers can create intricate designs and thin-walled components with aluminum sheet metal fabrication, making it indispensable for precision engineering applications.

High Recyclability

Sustainability is becoming an increasingly important consideration in material selection, and aluminum excels in this area. It is 100% recyclable without losing its properties, making it an eco-friendly choice.

- Environmental and Economic Benefits: Recycling aluminum consumes only 5% of the energy required to produce primary aluminum, significantly reducing carbon emissions. Industries such as automotive and construction increasingly rely on recycled aluminum to meet their sustainability goals.

Conclusion

The advantages of aluminum sheet metal fabrication—lightweight, corrosion resistance, thermal conductivity, ease of processing, and recyclability—underscore its critical role in various industries. From enhancing fuel efficiency in transportation to ensuring sustainability in construction, aluminum sheet metal fabrication continues to shape the future of industrial applications.

0