Table of Contents

Introduction to Polarizer Manufacturing

Polarizer are essential components in a variety of optical devices, including LCD screens, cameras, and sunglasses. Their primary function is to filter light waves, allowing only those aligned in a specific direction to pass through. This process not only improves contrast and clarity in images but also reduces glare and reflections.

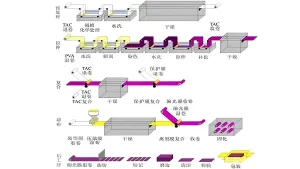

The manufacturing of polarizers is a sophisticated process that begins with the creation of a polyvinyl alcohol (PVA) film. This film serves as the foundation upon which the polarizing effect is built. The PVA is first extruded into a thin film, which is then subjected to a series of treatments to prepare it for the dyeing process.

The Dyeing Process

Dyeing is a critical step in polarizer production. It involves immersing the PVA film in a solution containing iodine or other dyes. The choice of dye depends on the desired properties of the polarizer. Iodine is commonly used because it forms long chains within the film that align during the stretching process, creating a polarizing effect.

Stretching: Aligning the Molecules

After dyeing, the film undergoes a stretching process. This is done by passing the film between rollers that rotate at different speeds, causing the film to stretch. The degree of stretching is carefully controlled, as it affects the alignment of the dye molecules and, consequently, the polarizing properties of the film.

Drying and Curing

Once stretched, the film is dried and cured. This step stabilizes the molecular alignment and sets the polarizing effect. The film is then laminated with triacetyl cellulose (TAC) protective film on both sides. The TAC film not only protects the delicate PVA film but also adds structural stability.

Applying the Adhesive Layer and Functional Films

The intermediate process involves applying a pressure-sensitive adhesive layer to the polarizer. This adhesive is crucial for attaching the polarizer to various substrates in the final product. Depending on the application, additional functional films, such as anti-glare or anti-reflective coatings, may also be applied.

Precision Cutting and Final Touches

The final stages of production include precision cutting of the polarizer to the required dimensions, marking for identification, and edging to remove any sharp or irregular edges. The finished polarizers are then carefully packaged to prevent damage during storage and transport.

Quality Control

Throughout the manufacturing process, quality control is paramount. Each step is monitored to ensure that the polarizers meet the exact specifications required for their intended use. The process requires not only advanced machinery but also skilled technicians who understand the nuances of polarizer production.

Conclusion

In conclusion, the manufacturing of polarizers is a detailed and precise process that requires a deep understanding of both chemistry and physics. From the initial film creation to the final packaging, each step is designed to produce polarizers that provide clear and accurate polarization, essential for the high-quality visual experiences we’ve come to expect from modern optical devices.

0