Table of Contents

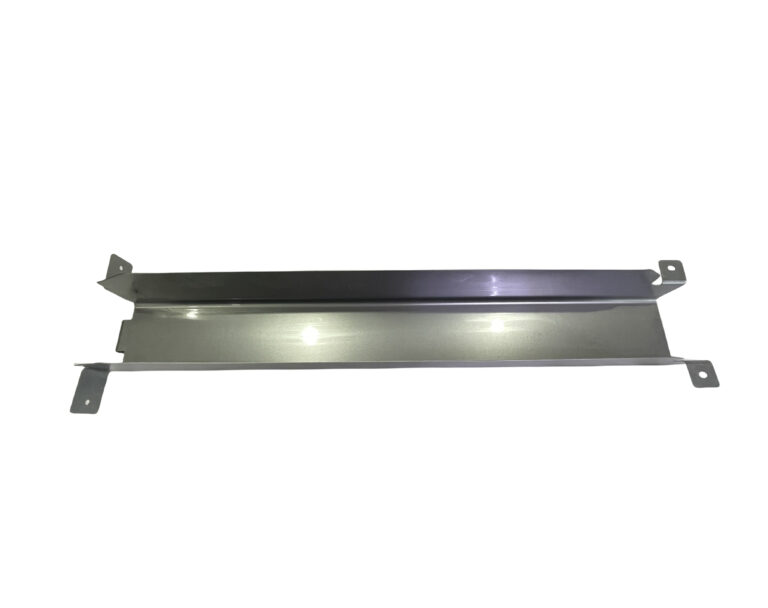

In an era of rapid technological advancement and process optimization, the manufacturing industry is continuously seeking methods to enhance efficiency, precision, and cost-effectiveness. This article provides an objective analysis of how digital transformation and lean manufacturing strategies are reshaping production practices. Central to our discussion is the sheet metal cutting service, which has become a critical element in achieving operational excellence and streamlined production workflows.

Digital Simulation and Process Optimization

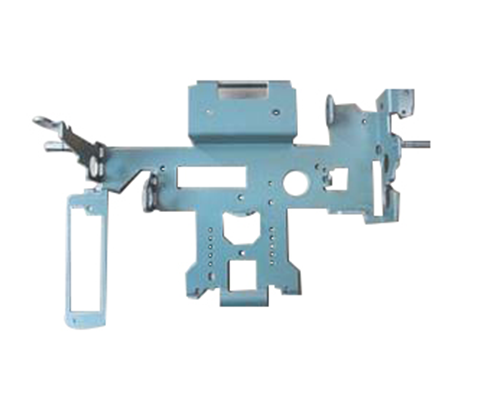

The integration of digital simulation tools into production processes has revolutionized traditional manufacturing practices. Advanced software now allows engineers to create virtual models that accurately simulate cutting patterns, stress distribution, and material behavior under various conditions. These simulations not only reduce the need for physical prototypes but also enable precise adjustments before production begins. By incorporating data analytics and real-time monitoring, manufacturers can predict potential issues, optimize cutting paths, and enhance overall production efficiency. This data-driven approach is proving essential for modern operations, where minimizing errors and maximizing output are key objectives.

Lean Manufacturing for Cost Efficiency

Implementing lean manufacturing principles has emerged as a powerful strategy for reducing waste and lowering production costs. By focusing on continuous improvement and value stream mapping, companies can identify inefficiencies throughout the production process. For instance, by streamlining workflows and eliminating redundant steps, the production cycle can be shortened without compromising quality. Operators are encouraged to adopt best practices that support standardized work procedures and just-in-time inventory management. This systematic reduction in waste and increased productivity not only lowers operational costs but also contributes to a more sustainable manufacturing environment. In this context, a well-organized sheet metal cutting service is fundamental to maintaining high-quality output while managing costs effectively.

Supply Chain Integration and Customization

The modern manufacturing landscape demands flexibility and rapid responsiveness to market changes. Integration with the broader supply chain plays a pivotal role in achieving these goals. By establishing seamless communication channels between design, production, and distribution teams, manufacturers can quickly adapt to custom orders and evolving client requirements. Collaborative planning and advanced scheduling systems help ensure that material requirements are met and that production deadlines are consistently achieved. This integrated approach enhances the overall responsiveness of the production process and supports a higher level of customization, which is particularly important for industries that rely on short-run production and rapid prototyping.

Quality Control and Continuous Improvement

Maintaining a high standard of quality is essential for any production process. Rigorous quality control measures, including real-time inspection systems and regular equipment calibration, help ensure that every product meets precise specifications. Operators are trained to monitor critical parameters and make necessary adjustments to maintain consistency throughout production runs. Additionally, the feedback loop established through continuous improvement initiatives allows manufacturers to address issues promptly and refine their processes. This commitment to quality and operational excellence not only drives customer satisfaction but also reinforces the reliability of the sheet metal cutting service in meeting rigorous industry standards.

Conclusion

The convergence of digital transformation and lean manufacturing strategies is redefining production efficiency and quality in modern fabrication. Through the use of advanced simulation tools, streamlined processes, and integrated supply chains, manufacturers are achieving unprecedented levels of precision and cost control. The evolution of the sheet metal cutting service is a prime example of how innovative approaches can lead to significant improvements in productivity and quality. As the industry continues to evolve, embracing these digital and lean methodologies will remain essential for companies striving to maintain a competitive edge.

0