Table of Contents

What is ABS polymer anti static agent?

ABS polymer anti static agent is an additive used for ABS resins. It is perfectly compatible with ABS resin, effectively eliminates static electricity hazards, and has good thermal stability and a lasting antistatic effect.

Its common physical properties are as follows: natural appearance is usually light yellow granular solid, and its melting point is 165-195 degrees.

The amount of addition during use varies according to the type of resin. The dosage is generally 10-25%, which can make the surface resistance of the product reach 10E7-10E9. In terms of usage, the anti static agent can be used together with other additives, but it may absorb some additives. It is recommended to increase its addition amount to achieve the same effect. In practical applications, the appropriate addition amount should be determined according to the processing conditions, product form, and the degree of antistatic effect required. The internal addition method is adopted, that is, the anti static agent is directly added to the resin to process the product, or it can be made into an antistatic masterbatch in advance and then mixed with blank resin for processing so that the uniformity is better and the effect is better. In terms of packaging, it is generally packaged in plastic bags and should be stored in a cool and dry place. It is strictly forbidden to expose it to the sun or rain. Each bag is 25kg. The container must be sealed after each use to prevent the product from getting wet.

What are the advantages and disadvantages of ABS polymer anti static agents?

ABS polymer anti static agent has the following advantages:

1. Highly efficient antistatic performance: It can significantly reduce the surface resistance of ABS materials and effectively eliminate static electricity accumulation and discharge.

2. Long-lasting stability: The antistatic effect has good durability and can maintain relatively stable antistatic performance during the service life of the product.

3. Good compatibility: It has good compatibility with ABS resin, is not prone to precipitation, migration, and other problems, and does not affect the physical properties and appearance of the material.

4. High thermal stability: It can withstand high temperatures during processing and is not easy to decompose.

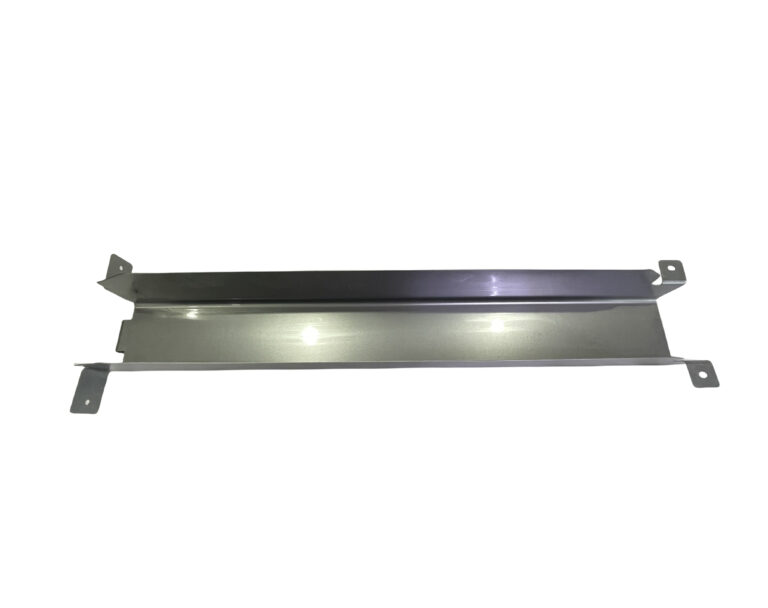

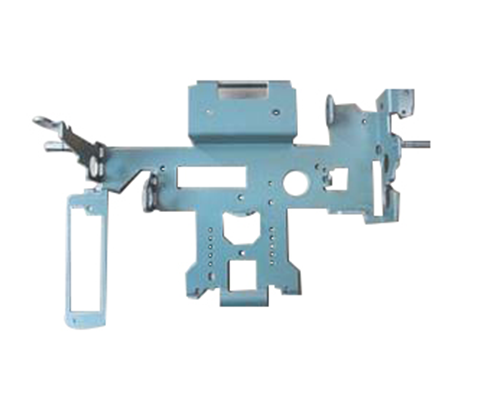

5. Wide range of applications: It can be used in the production of a variety of ABS products, such as electronic and electrical housings, automotive parts, etc.

However, it also has some disadvantages:

1. High cost: Compared with some traditional anti static agents, the price may be relatively expensive.

2. It may affect certain properties of the material: For example, it may reduce the tensile strength and impact strength of the material to a certain extent.

What factors affect the dosage of ABS polymer anti static agent?

The dosage of antistatic agent to ABS polymer needs to take into account multiple factors. Here are some suggestions:

1. Antistatic requirements: Determined according to the specific requirements of the product’s antistatic performance. If a lower surface resistance or a stronger antistatic effect is required, a relatively high amount of addition may be required.

2. Processing conditions: Including processing temperature, screw speed, extrusion output, etc. Different processing conditions may affect the dispersion and effect of the anti static agent in ABS, and thus affect the amount of addition.

3. Product form: For example, products of different forms such as film, sheet, container, etc. may require different amounts of addition to ensure uniform antistatic performance.

4. Type of anti static agent: Different types of anti static agents may have different activities and efficiencies, so the amount of addition required to achieve the same antistatic effect may also be different.

5. Material formulation: The characteristics of ABS resin itself and the presence of other additives may affect the effect of the anti static agent, so the amount of addition needs to be adjusted.

In addition, anti static agent suppliers can usually provide some reference addition ranges or suggestions, which can be initially selected based on actual conditions and then optimized through experiments. After determining the amount of addition, the consistency of the production process should be maintained to ensure the stability of the antistatic performance of the product. At the same time, attention should also be paid to the compatibility between the anti static agent and other additives, as well as the impact of the environmental conditions during the use of the product on the antistatic performance.

0