Table of Contents

UV Lasers are versatile tools that can assist in various laser processing operations. Known for their precision, UV lasers excel in marking and engraving tasks. Understanding the fundamentals of your UV marking kit is essential for effective use. This guide will enhance your knowledge about UV laser technology.

Importance of UV Laser Types

The type of UV laser you choose is crucial. There are three primary types: excimer, exciplex, and molecular fluorine.

Excimer Lasers operate at a wavelength of 193 nm, generating minimal heat, making them suitable for delicate materials. They are the fastest in terms of etching speed but are costly and not widely available.

Exciplex Lasers are hybrid gas-solid state lasers that emit light waves at 355 nm (or double this value). They are more affordable than excimer lasers but are slower in terms of etching speed.

Molecular Fluorine Lasers have short wavelengths that allow deeper penetration into materials, making them ideal for working with thicker substrates like glass.

Materials Suitable for UV Laser Cutting

UV laser cutters have the unique capability to process a wide range of materials due to their wavelength of around 400 nanometers, which is absorbed by almost any substance. They are especially effective on:

- Stainless Steel

- Aluminum

- Titanium

- Copper

- Brass

- Carbon Fiber Composites

Additionally, these lasers are adept at cutting ceramics and various polymers.

Components of a Typical UV Laser Starter Kit

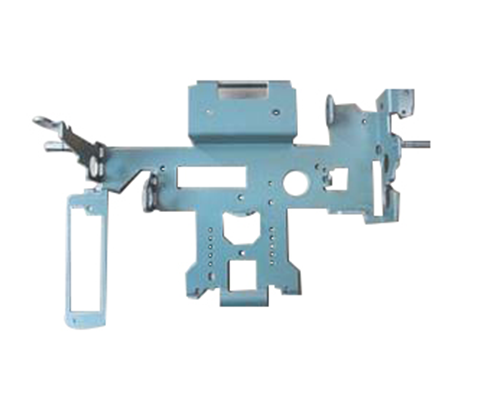

UV laser starter kits provide an excellent introduction to UV marking technology. They help users learn about lasers and their applications. A typical starter kit usually includes:

- Laser pointer module (the laser itself)

- High-power driver board (to power the laser)

- Glass lens

- Clear plastic lens

- Safety goggles

- Aluminum heatsink (for cooling)

- Button switch (for operation control)

Where to Purchase a UV Laser

If you’re considering adding UV lasers to your operations, understanding their benefits is vital. When selecting a UV laser, ensure that you choose a reliable source that offers comprehensive support and quality products.

Benefits of Choosing Quality UV Lasers

Expert Guidance: Look for suppliers who assist in the entire process, from selection to installation and maintenance. Having experts available can enhance your experience.

Streamlined Process: A simplified purchasing and usage process can save time and effort, allowing you to focus on your core activities. Make sure the supplier has thought through the logistics to facilitate easy use.

Product Quality: Quality is paramount when it comes to UV lasers. Ensure that the products offered are reliable and accurate without compromising on price.

Conclusion

Understanding the capabilities of UV lasers and how to effectively use your UV laser kit can significantly impact your projects. With the right knowledge and resources, you can maximize the potential of these powerful tools. If you have more questions or need further information, don’t hesitate to seek expert advice.

0