Table of Contents

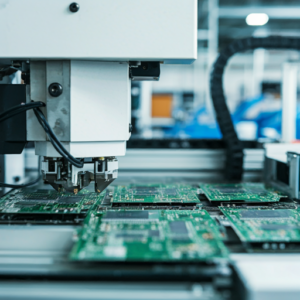

The SMT machine (Surface Mount Technology machine) has become a cornerstone in modern electronics manufacturing. This innovative equipment streamlines the process of placing electronic components onto printed circuit boards (PCBs), ensuring efficiency and precision. Its adoption has transformed industries by enabling faster production and supporting the growing demand for compact, high-performance devices.

Importance and Background of SMT Machines

The SMT machine plays a vital role in electronics assembly. Before its development, manufacturers relied on through-hole technology, which was time-consuming and less suitable for miniaturized components. SMT machines were introduced to meet the need for higher efficiency and accuracy in the assembly process. Today, they are essential in producing advanced electronic devices like smartphones, medical instruments, and automotive systems.

How Does an SMT Machine Work?

An SMT machine operates in a systematic sequence:

Solder Paste Application: A stencil printer applies solder paste to specific areas of the PCB where components will be mounted.

Component Placement: Using robotic arms and vision systems, the SMT machine picks and places components precisely on the PCB.

Reflow Soldering: The PCB is passed through a reflow oven, where the solder paste is melted and solidified, securing the components to the board.

Advanced SMT machines are equipped with high-speed cameras, sensors, and AI algorithms to ensure accuracy and adapt to various component types and sizes.

Applications of SMT Machines

The SMT machine is widely used in industries such as telecommunications, automotive, aerospace, and consumer electronics. For instance, in the production of smartphones, SMT machines enable the placement of tiny components like resistors and capacitors on densely packed PCBs.

In the automotive industry, SMT machines are used to produce control units and sensors for advanced driver-assistance systems (ADAS). Similarly, medical equipment manufacturers rely on SMT machines to build compact devices like pacemakers and diagnostic tools.

Why Are SMT Machines Essential?

The significance of an SMT machine lies in its ability to meet the demands of modern electronics manufacturing. It enhances productivity, reduces costs, and ensures consistent quality. Moreover, as devices become increasingly compact and complex, SMT technology is indispensable for achieving precise assembly.

In conclusion, the SMT machine is not only a technological marvel but also an indispensable tool in today’s electronics manufacturing landscape. Its efficiency, accuracy, and versatility continue to drive innovation across various industries.

0