Table of Contents

Who wouldn’t want something unique? Something that reflects their personality? Customized cases have become a popular way for people to express themselves in unique ways. The ability to customize a phone case lets people’s imaginations run wild.

Variety of Customization Options

There is a large variety of customization options when it comes to custom cases. From the materials used to the design and customization techniques employed.

Material Choice

The choice of material plays a vital role when it comes to the look and feel of the case. Different materials give you different levels of texture, looks, and protection.

Silicone

When in search of durable, flexible, lightweight, and shock-absorbing cases, silicone is usually the go-to material. It also has a high grip making it preferred by most.

Leather

Leather cases tend to have a more unique and premium feel. They are often used by people in search of durability and style, adding a unique character to the case.

Hard Plastic

Hard plastic cases are mostly used by engineers and industrial workers. They offer strength, rigidity, and durability, providing top-of-the-range protection against impacts and scratches. These cases also provide a smooth surface for high-quality prints and advanced designs.

Design Flexibility

When getting a customized phone case, one can come up with any design and bring it to life. The design styles are unlimited as there are endless possibilities when it comes to customizing a phone case.

Personal photos

Users can use their favorite photos, portraits, or even snapshots. This option creates room for a personal and memorable design

Artistic Patterns

There is a large variety of patterns and designs for those who like art. Those patterns add creativity and elegance to the case.

Text and Quotes

Users can easily add inspirational quotes, names, initials, and many more. This simple add-on can convert a regular case into a meaningful reminder.

Customization Techniques

The material and the design are not the only factors that contribute to the final look and feel, the techniques used also play a vital role in bringing the design to life. What are some of the techniques used to bring these ideas back to life?

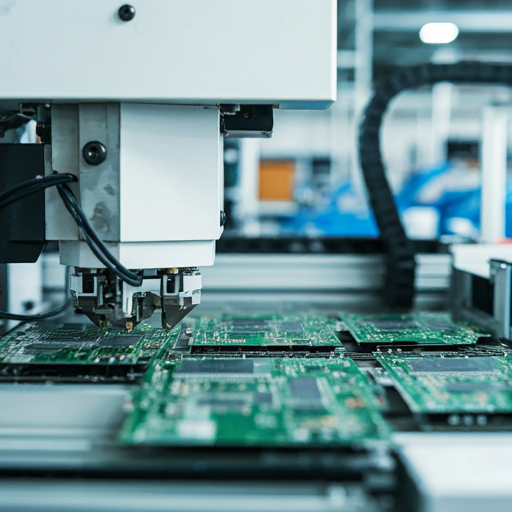

Printing

High-resolution printing is common for creating customized phone cases. It provides vibrant and detailed designs that cover the entire case.

Engraving

Engraving is used to achieve an elegant design. Engraving mainly involves etching the text or design in the case. It’s an excellent choice and is mostly done on leather and metal.

Embossing

Embossing creates a raised design to a case by adding texture and dimension to it. It’s often used in leather or silicone cases.

These techniques ensure that the cases are customized and created with precision and care. Resulting in a high-quality product that can easily stand out.

Conclusion

Creating a customized phone case has been made easier by the use of available online tools and design platforms. They are user friendly and someone with no experience can effortlessly create something unique. The drag-and-drop functionality along with a wide selection of templates and designs make the process interesting, enjoyable, and straightforward. This also ensures that anyone can bring their vision to life without the need for a professional.

0