Table of Contents

Filling and capping are integral parts of manufacturing industries. They ensure the products are accurately filled. The processes are also responsible for securely sealing the item. Filling capping machines have modernized routine operations. As a result, the manufacturer experiences efficiency. The precision is a lot better than manual methods. Let’s learn how these machines streamline production and improve product quality.

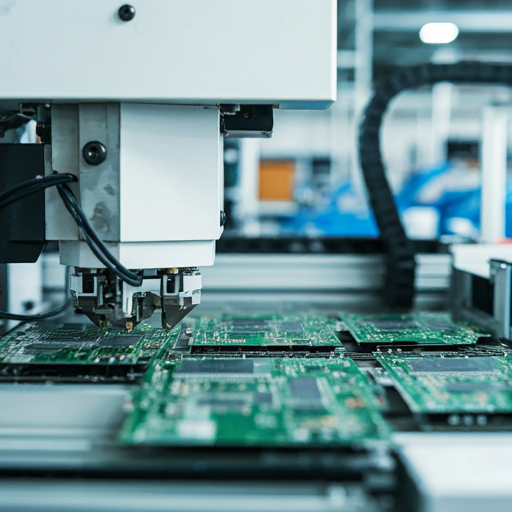

Efficiency in Automation

Filling and capping machines automate processes. Thus, significantly boosting efficiency. They are capable of filling and capping hundreds of containers per minute. Resultantly, these machines reduce production time and labor expenses. By automating these tasks, manufacturers can meet clients’ requirements. At the same time, the machines maintain consistency and accuracy in packaging.

High Precision

Filling capping machines offer precise filling and sealing. Advanced technology means each container is filled to the exact volume. It reduces waste. The feature ensures uniformity. Capping machines apply caps with the right force. As a result, the machines ensure they are securely sealed. The lids are not too tight or too loose.

Versatility for Diverse Products

These machines are versatile. They handle a wide range of products, such as liquids, powders, and granules. Moreover, the filling and capping algorithm will accommodate various container sizes and types. The features make them suitable for different packaging needs. Whether filling bottles, jars, or containers, filling capping machines are adjustable to meet specific production requirements.

Enhancing Product Quality

Using filling capping machines improves product quality because each container is filled and sealed correctly. It reduces the risk of contamination and product spoilage. The products reach consumers in optimal condition. Additionally, automation reduces the risk of human error. The product quality and consistency are further improved.

Meeting Regulatory Standards

Filling and capping machines will meet regulatory standards in industries such as food, pharmaceuticals, and cosmetics. They are constructed with materials that comply with industry regulations. Moreover, the machines are equipped with features that ensure product safety and hygiene. By using filling and capping machines that comply with hygiene standards, manufacturers can ensure compliance. Companies avoid costly fines, or stock recalls.

Increasing Production Capacity

Filling and capping machines will increase production capacity compared to manual methods. The machines are operating continuously without being tired. It allows for day and night production cycles. It increased capacity. In addition, the machine enables manufacturers to meet growing demand and expand their market share.

Minimizing Labor Costs

Automation with machines reduces the need for manual labor. Thus, the labor costs are significantly lowered. When eliminating repetitive manual tasks, manufacturers can relocate labor to more value-added activities. The strategy improves overall efficiency. The staff is highly motivated to reach the goals of the company.

Conclusion

Filling and capping machines are indispensable in modern-day manufacturing. They offer unmatched efficiency, precision, and diversity. The machines streamline processes and improve efficiency and product quality. Manufacturers are encouraged to invest in such machines that help manufacturers stay competitive. They are able to meet high-demand requirements. The best part is that the products reach consumers in optimal condition. You can contact ZONESUN packaging for more details on filling capping machines.

0