Table of Contents

Sapphire has proven over the years to be a very useful resilient material. It can be used both chemically and mechanically. The semiconductor community and various other communities have benefited from sapphire exploration as a device substrate.

The workhouse of some industries is silicon. However, silicon has proven to be inappropriate in certain applications. The reason the sapphire substrate has generated huge interest.

Bear with me, because I am going to show you how sapphire substrate can be game-changing in semiconductor devices. But, before I jump into the details, let’s discover more about sapphire.

What is Sapphire

Sapphire is a precious gemstone that has as primary constituents many igneous rocks and aluminum oxide. It has been highly-priced as a gemstone since about 800 BC.

Small amounts of titanium and iron influence its color. What’s however interesting is that sapphire is unevenly colored and even when colored it is mostly dichroic; meaning its color changes with the direction of view.

The question is how will it be game-changing in semiconductor devices?

To illustrate that, I’ll tell you more about the distinct properties of the sapphire substrate. I’m sure you’ll get a glimpse of how special this gemstone is.

Distinct Properties of Sapphire Substrate

- Sapphire serves as an amazing electrical insulator, making it ideal for various electrical applications.

- It is also very resistant to radiation. This makes it ideal for the creation of electrical devices with limited performance issues during radiation exposure.

- With a Mohs hardness of about 9, the sapphire material is very hard, comparable only to the diamond with a Mohs hardness of 10.

- The melting point of sapphire material is 2050 degrees Celsius.

I believe you getting a clear picture of just how different sapphire substrate can be, and how game-changing it could also prove to be in your industry.

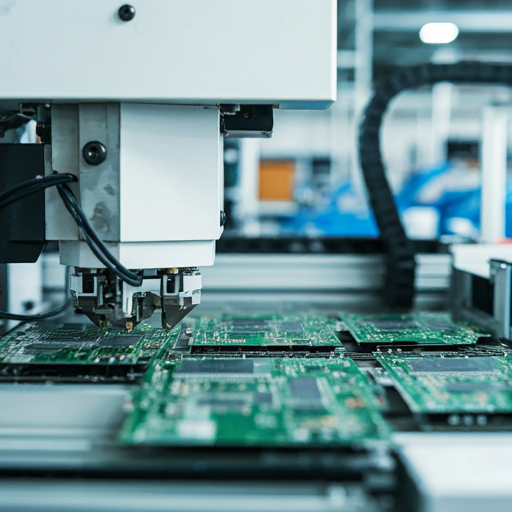

How to apply sapphire substrates in semiconductor electronics

Here we go. According to tested and proven strategies, silicon can be deposited on sapphire to create silicon on an insulator device structure. We have referred this procedure to as silicon on sapphire (SOS).

This technology has revealed enormous benefits over bulk silicon applications. Silicon dioxide turns to have a thin layer of buried oxide serving as an insulator barrier. Thus, sapphire is a better insulator than silicon dioxide.

Sapphire on silicon is an insulator that guarantees an infinite dimension.

The fabrication of SOS wafers is feasible. Done well, it could generate mind-blowing benefits, especially in applications like RF technology.

Also, it’s worthy of note that sapphire substrates-based integrated technologies are a well-established niche in the RF industry. They allow the integration of high-performance analog devices with digital CMOS circuitry on the same substrate.

Conclusion

The sapphire substrate will guarantee the higher performance and durability of your devices. The possibilities are endless. It’s time you take advantage of this evolution that’ll make your devices desirable.

We offer custom-made sapphire sulfates that’ll suit your every need.

0