Table of Contents

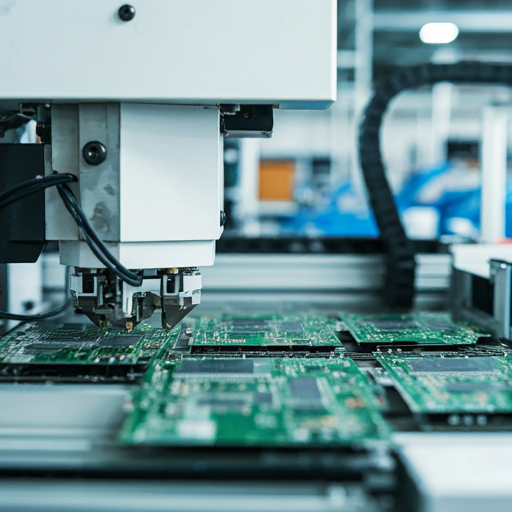

In modern manufacturing, efficiency is key to keeping production processes smooth and cost-effective. One essential tool for achieving this is the assembly line roller table. This simple yet effective piece of equipment plays a crucial role in enhancing productivity by helping move parts and products through different stages of assembly. But how does an assembly line roller table work, and what makes it so beneficial in various industries? Let’s dive into the details.

What is an Assembly Line Roller Table?

An assembly line roller table is a type of conveyor system designed to move products or materials through various stages of the assembly process. It consists of a series of rollers that are mounted on a frame, allowing items to be easily pushed, pulled, or moved along a predetermined path. Roller tables are often integrated into assembly lines where they provide smooth, continuous movement, reducing the need for manual labor and minimizing the risk of errors.

These tables come in different sizes and configurations, depending on the specific needs of the production line. They are typically used in environments where products need to be moved across short distances or when the assembly process requires workers to interact with the items at specific points along the line.

Advantages of Using an Assembly Line Roller Table

Enhanced Productivity: One of the key benefits of an assembly line roller table is its ability to streamline the material handling process. By facilitating the smooth movement of products between different assembly stations, the roller table allows workers to focus on their tasks rather than manually transporting materials. This increases overall efficiency and helps speed up production times.

Reduced Labor Costs: With the automation provided by the roller table, businesses can reduce their reliance on manual labor. This lowers labor costs while ensuring that workers can concentrate on more complex or critical tasks, leading to a more cost-effective operation.

Durability and Versatility: Assembly line roller tables are built to last, with heavy-duty rollers designed to handle a variety of materials and products. Their versatility makes them suitable for use in a wide range of industries, from automotive manufacturing to electronics assembly, packaging, and more.

Flexible Design: These roller tables can be customized to fit the specific needs of a production line. Whether it’s adjusting the length of the table or adding features like adjustable heights or curved sections, the assembly line roller table can be tailored to suit the layout and workflow of any facility.

How Does an Assembly Line Roller Table Work?

The assembly line roller table works through a simple yet effective mechanism. It uses a series of rollers mounted on a frame to move items from one station to another. Depending on the design, these rollers can be powered or free-rolling.

In a powered roller system, the rollers are driven by a motor, often connected to a belt or chain that turns the rollers. This motorized movement ensures a continuous and controlled flow of materials along the assembly line, reducing the need for manual intervention. Powered roller tables are often used when items need to be moved at a constant speed or when the system needs to accommodate heavier loads.

On the other hand, a free-rolling assembly line roller table relies on gravity or manual force to move items. These systems are typically used in areas where less control over speed is needed, and they are often found in environments where products need to be moved in both directions.

Regardless of the type, the assembly line roller table is designed to reduce friction and allow for smooth, easy movement of materials. This helps maintain a continuous flow, ensuring that products reach the next stage of the assembly process in a timely manner.

Applications of Assembly Line Roller Tables

Assembly line roller tables are used in various industries, each benefiting from their ability to streamline processes and improve efficiency. In automotive manufacturing, they are used to move car parts through different stages of assembly, from engine installation to final inspection. In packaging, roller tables help move boxes or packages through filling, sealing, and labeling stations. Additionally, they are used in warehouses and distribution centers to efficiently handle goods, sort packages, and reduce congestion in high-traffic areas.

They are also widely utilized in industries like electronics, metalworking, and logistics, where products need to be moved smoothly and reliably.

Conclusion

The assembly line roller table is an essential component in modern manufacturing environments. By providing a reliable and cost-effective way to move materials along an assembly line, it enhances productivity, reduces labor costs, and improves overall workflow. Its versatility and customization options make it suitable for a wide range of applications, from automotive manufacturing to packaging and logistics. If you’re looking to optimize your production process, an assembly line roller table may be the solution you need.

0