The sapphire wafer is an easy and efficient way to grow single-crystal sapphire crystals in large quantities. Within the industry, this astonishing growth process is a widely accepted production procedure, and its simplicity makes it an appealing alternative to more sophisticated fabrication techniques.

What is a Sapphire Wafer?

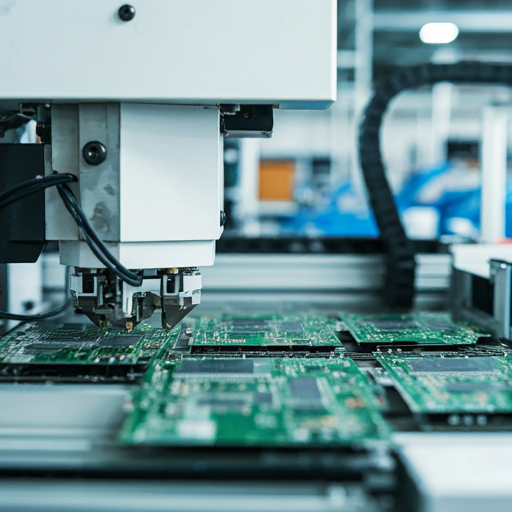

A sapphire wafer is an ultra-thin slice of synthetic sapphire, usually less than a millimeter in thickness. Sapphire wafers are used in the fabrication of integrated circuits and microelectromechanical systems, among other things.

How are sapphire wafers made?

Sapphire wafer manufacturing process:

Sapphire is one of the hardest materials on Earth, and it’s used to make everything from cutting-edge medical supplies to infinitesimal window LEDs. But how are sapphire wafers made? Using a hydrothermal process, of course!

Sapphire is corundum that contains a large amount of aluminum. Because sapphire is so hard, it takes special equipment and processes to make it into wafers. To create sapphire wafers, mix powdered aluminum with Cornish acid (H4SiO4) in an aqueous solution. The solution is then treated with ammonium chloride (NH4Cl) and hydrogen bromide (HBr) to produce crystalline corundum seed crystals.

The next step is to anneal these seed crystals: through heating and cooling cycles, they gradually expand and recrystallize into larger corundum pieces. The final stage is grinding the now enormous pieces into thin sheets. These thin sheets are then cut into squares or rectangles to become sapphire wafers!

Sapphire Wafer Advantages and Disadvantages:

Advantages–: Sapphire is a high quality, durable, and versatile material that can be used in many applications. Sapphire wafers offer compelling benefits such as high hardness and a low coefficient of thermal expansion. In the hi-tech world, you might have come across different types of wafers that are used for test and measurement applications. Among these are sapphire wafers. Geographically, the manufacture and applications of sapphire wafers originated in the Asia Pacific. It is important to examine the various advantages of using sapphire wafers over other materials.

Disadvantages–: The sapphire wafer market is estimated to grow at a significant pace over the next four years. Numerous industries are relying significantly on sapphire wafers as an alternative material to regular silicon wafers. However, even as the industry gears up for exponential growth, it still carries some disadvantages. These affect not only its parts but also impact the overall ecosystem.

Properties of Sapphire Wafer:

Sapphire wafers are known for their high melting point, durability, and ability to withstand extreme heat. When heated to a high temperature, they glow brightly and can be used as light sources in dark situations. They are also known as an ingredient in making semiconductors, as they have special properties that allow them to conduct electricity.

Sapphire Wafer is a silicon dioxide wafer that is used to make micro-thin semiconductor devices including LEDs, lasers, and solar cells. It is also used in applications that require a high degree of hardness, such as in medical applications where it is useful in removing plaque from blood vessels.

0