Table of Contents

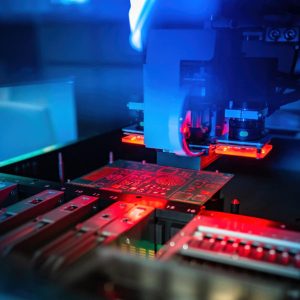

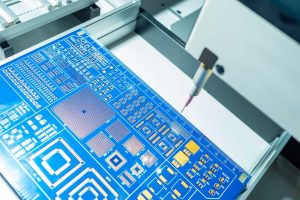

With a wide array of PCB types available, each designed for specific applications and requirements, understanding these differences is crucial for engineers, designers, and manufacturers alike.

This article delves into the most common PCB types, their characteristics, and their applications, empowering you to unlock the full potential of your electronic designs.

Rigid PCBs: Stability and Reliability

Rigid PCBs are the most commonly used type in the industry. Made from a solid substrate, typically fiberglass or epoxy resin, they provide excellent mechanical support and durability. Rigid PCBs are ideal for applications where stability and reliability are paramount, such as in consumer electronics, automotive systems, and industrial machinery. Their rigid structure allows for precise component placement and is suitable for high-density designs.

Flexible PCBs: Adaptability and Compact Design

The flexibility in PCBs makes them ideal for applications where space is limited or where the board must fit into tight spaces, such as in wearable technology, medical devices, and smartphones. Flexible PCBs can reduce the overall weight of a device and improve its design by allowing for more compact layouts.

Rigid-Flex PCBs: The Best of Both Worlds

Combining the benefits of both rigid and flexible PCBs, rigid-flex PCBs are designed with both rigid and flexible sections. This type is particularly useful in applications that require a combination of durability and flexibility, such as aerospace and military electronics. Rigid-flex PCBs can significantly reduce the number of interconnections needed, leading to lighter and more compact designs.

Multilayer PCBs: High-Density Circuits and Connections

This design allows for a higher density of circuits and connections, making them suitable for complex electronic devices. Multilayer PCBs are commonly used in high-performance applications such as computers, telecommunications equipment, and advanced medical devices. They enable efficient use of space while maintaining signal integrity.

High-Frequency PCBs: Specialized for Radio Frequency Applications

High-frequency PCBs are specifically designed for applications that operate at radio frequencies, such as wireless communication devices and radar systems. These PCB types are constructed using materials that minimize signal loss and maintain signal integrity at high frequencies. The choice of substrate material is critical in high-frequency applications, as it directly impacts performance.

Conclusion: Empowering Innovation with the Right PCB Type

Understanding the different PCB types is essential for selecting the right board for specific applications. Each type offers unique advantages and is suited for various environments and requirements. Rigid PCBs provide stability, while flexible PCBs offer versatility in design. Rigid-flex PCBs bridge the gap between the two, and multilayer PCBs cater to complex designs. High-frequency PCBs are tailored for specialized applications.

As technology continues to evolve, the demand for innovative PCB types will grow. By staying informed about the characteristics and applications of these boards, professionals in the electronics industry can make better decisions in their design and manufacturing processes. Whether developing consumer electronics or advanced communication systems, understanding PCB types is a fundamental aspect of successful electronic design.

By embracing the diverse world of PCB types, you can unlock the full potential of your electronic designs, pushing the boundaries of what’s possible. From compact and flexible devices to high-performance and specialized systems, the right PCB type can make all the difference in bringing your innovative ideas to life.

0